Product labeling is essential in industries that are subject to regulations. It guarantees that items are safe, adhere to legal standards, and are utilized properly by consumers who depend on them. This blog outlines the concept of labeling, the reasons behind its regulation, and the methods companies utilize for product labeling in these industries, using straightforward language suitable for both seasoned experts and newcomers.

What Is Labeling?

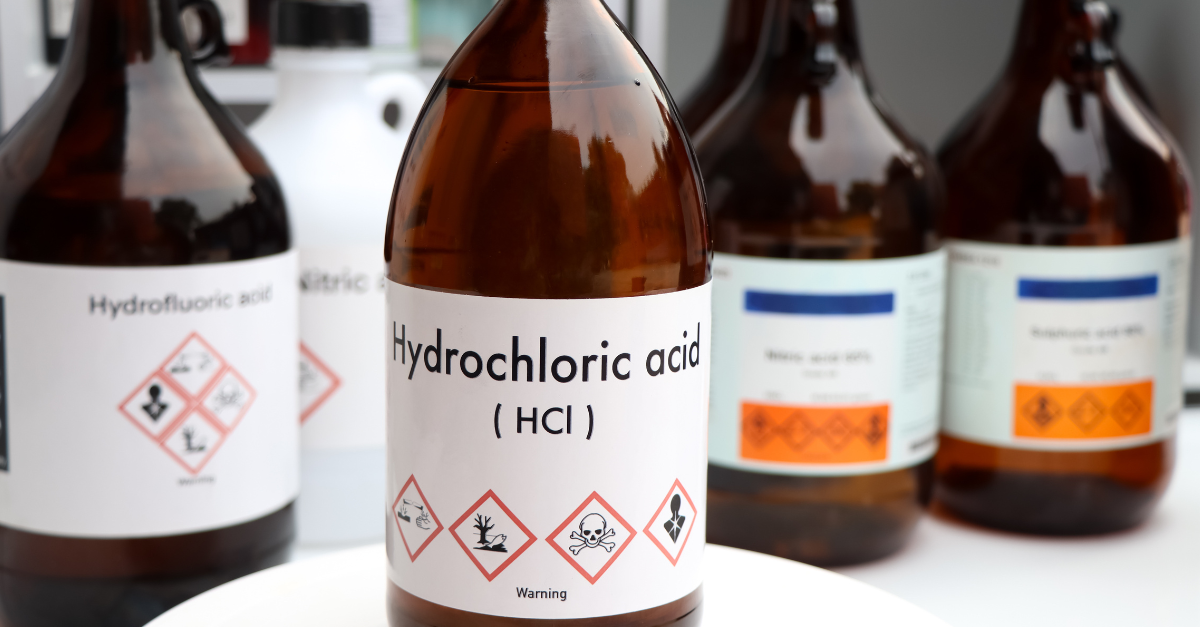

Labeling refers to the information provided on or with a product that explains what the product is, how it should be used, and any risks associated with its use.

In regulated industries, labeling is not limited to what appears on a package. It includes any written, printed, or graphic information that accompanies a product throughout its lifecycle. This can cover physical labels, instructions for use, package inserts, and, increasingly, digital or electronic labeling.

Regulatory authorities take a broad view of labeling. For example, the U.S. Food and Drug Administration (FDA) defines labeling as any material that accompanies a product, even if it is not physically attached to it. This definition reinforces why labeling must be controlled and compliant at all times.

Why Labeling Matters in Regulated Industries

Labeling matters because it directly affects safety, compliance, and trust. In regulated sectors such as pharmaceuticals, medical devices, and life sciences, labeling is one of the primary ways critical information is communicated to healthcare professionals, patients, and consumers. Incorrect or unclear labeling can lead to misuse, delays in treatment, or serious safety risks.

From a regulatory standpoint, labeling also serves as evidence that a product meets legal and quality requirements. This is why regulated product labeling is treated as a compliance function rather than a design or marketing activity.

What Information Is Typically Included on a Label?

While product labeling requirements vary by industry and region, most regulated labels are expected to provide clear, accurate, and consistent information about the product.

This typically includes identification details, intended use, safety information, and traceability data. International standards and regulatory guidance help ensure that this information is communicated in a consistent way, even across global markets.

For example, standards such as ISO 15223 define commonly used symbols for medical device labeling, helping reduce language barriers and improve clarity worldwide.

How Labeling Differs Across Regulated Industries

Although the core purpose of labeling remains the same, product labeling in regulated industries differs based on the type of product and the risks associated with it.

Pharmaceutical labeling places strong emphasis on dosing, contraindications, and clinical information. Medical device labeling focuses on intended use, operating instructions, and risk mitigation. In life sciences and biotechnology, labeling often includes detailed handling, storage, and traceability requirements.

Organizations such as the FDA, the European Medicines Agency (EMA), and the World Health Organization (WHO) each set expectations for labeling within their regulatory frameworks, reflecting the specific risks and use cases of different products.

What Makes Labeling “Regulated”?

Labeling becomes regulated when it is subject to formal oversight and enforceable rules.

This means label content must meet defined requirements, follow approved formats, and remain consistent across regions and versions. Changes to labeling are typically controlled through formal review and approval processes, with documentation maintained as proof of compliance.

In the United States, labeling regulations such as 21 CFR Parts 201 and 801 outline labeling expectations for drugs and medical devices, making labeling a legally binding component of product compliance.

Common Labeling Mistakes and Why They Happen

Most labeling issues are not caused by a lack of regulatory knowledge. They are usually the result of fragmented processes.

When labeling content is managed across spreadsheets, emails, and disconnected systems, it becomes difficult to maintain consistency and control. Small changes can take longer than expected, and outdated content may be reused unintentionally. Over time, these gaps increase the risk of non-compliance and errors.

This is one of the most common challenges affecting product labeling compliance in regulated organizations.

How Companies Can Manage Labeling More Effectively

Managing labeling effectively starts with recognizing it as an end-to-end process, not a one-time task.

Organizations that perform well in this area typically focus on centralizing approved content, improving visibility into label versions, and strengthening review and change control workflows. This allows teams to respond more quickly to regulatory changes while reducing the risk of errors and rework.

A structured approach to labeling helps organizations remain compliant, scale globally, and protect both patients and brand reputation.

Key Takeaways

Product labeling is a critical compliance function in regulated industries. Understanding what labeling is, how regulated product labeling works, and why product labeling requirements exist helps organizations reduce risk and operate more effectively. Strong product labeling compliance depends on clear processes, consistent content, and regulatory awareness throughout the product lifecycle.

Want to Go Deeper into Global Labeling Readiness?

If you’re navigating increasing regulatory complexity, evolving global requirements, or growing pressure to scale faster without increasing risk, our latest research can help.

Download our free white paper, Kallik’s 2026 Global Labeling Readiness Report, to explore how global manufacturers are preparing for the future of product labeling, where common gaps still exist, and what leading organizations are doing differently.

So, how confident are you that your labeling processes are ready for what comes next? Speak to one of our labeling and artwork experts today to find out more. Fill in a form, email enquiries@kallik.com or check out our case studies to see real-world examples of how we’ve helped some of the biggest global manufacturers.

Subscribe to our newsletter for all the latest label and artwork news

Frequently Asked Questions About Product Labeling

What is labeling in regulated industries?

Labeling in regulated industries refers to the information provided on or with a product that explains its identity, intended use, and safety considerations. This information is governed by regulations to ensure products are used correctly and safely.

What is the difference between labeling and packaging?

Packaging refers to the physical container or materials that hold a product. Labeling refers to the information that accompanies the product, including text, symbols, instructions, and warnings. In regulated industries, labeling can exist separately from packaging and is still subject to compliance requirements.

Why is product labeling regulated?

Product labeling is regulated because it directly affects safety, compliance, and traceability. Regulators rely on labeling to ensure products are used as intended and that risks are clearly communicated to users.

What are product labeling requirements?

Product labeling requirements define what information must be included on a label, how it must be presented, and how changes are controlled. These requirements vary by industry, product type, and region, but typically include identification, intended use, safety information, and traceability details.

Who is responsible for product labeling compliance?

Product labeling compliance is usually a shared responsibility across regulatory affairs, quality, manufacturing, and supply chain teams. Clear ownership and structured processes are essential to ensure labeling remains accurate and compliant over time.

What happens if product labeling is incorrect?

Incorrect product labeling can lead to regulatory findings, product recalls, delayed market access, or safety risks. Even minor labeling errors can have serious consequences in regulated industries.

How does labeling differ across regulated industries?

While the core purpose of labeling is the same, the specific requirements differ by industry. Pharmaceuticals, medical devices, and life sciences products each have unique labeling expectations based on how the product is used and the risks involved.

How can companies improve product labeling compliance?

Companies can improve product labeling compliance by centralizing labeling content, strengthening review and approval workflows, and improving visibility into label versions and changes. Treating labeling as a controlled process rather than a manual task helps reduce risk and errors.