How Digital Product Passports Enhance Packaging Transparency

Digital product passports are a serious hot topic in the packaging industry right now. Having attended the Packaging Innovations and Empack 2026 event at Birmingham’s NEC this week, it was clear that businesses are keen to understand how digital product passports are reshaping supply chains by improving transparency, traceability, and compliance. So in this week’s blog, we take a look at what digital product passports are, why the EU is pushing for them, and how they’ll affect packaging.

What Are Digital Product Passports?

Let’s start with the basics, what is a digital product passport? Digital product passports are structured digital records that capture data across a product’s entire lifecycle. This includes sourcing, manufacturing, distribution, environmental impact, and end-of-life instructions.

So in simple terms, a digital product passport is like a digital birth certificate and diary for a product. It records where the product came from, what it’s made of, how it was manufactured, and what should happen to it at the end of its life.

This information is all accessible through QR codes, NFC tags, or similar technologies, allowing regulators, supply chain partners, and consumers to view verified product information instantly. Not only is this a major time-saver, but can also provide major benefits when it comes to sustainability and traceability.

A digital product passport may include:

- Raw material origins

- Manufacturing and labor practices

- Carbon footprint data

- Compliance documentation

- Recycling and disposal guidance

The EU Push for Digital Product Passports

The European Union is leading adoption through its Green Deal and broader sustainability regulations. EU digital product passports are designed to increase product transparency, reduce environmental impact, and combat counterfeiting.

This regulatory momentum is influencing global markets. As more regions introduce similar requirements, companies that implement digital product passports early will be better prepared for evolving compliance standards.

For brands operating internationally, this shift makes digital product passports a strategic investment, not just a regulatory requirement. So if you’re wanting to stay competitive – which we assume you are – this is something you’re going to want to be on top of.

How Digital Product Passports Improve Packaging Transparency

Digital product passports transform packaging into a gateway to verified product data. By embedding scannable codes into packaging, brands connect physical products to dynamic digital records. Consumers can instantly access information about origin, materials, sustainability metrics, and recycling instructions.

This creates:

- Greater visibility across the supply chain

- Real-time product data updates

- Clearer recycling and disposal guidance

- Stronger brand transparency

Here at Kallik, we’ve always shouted about packaging being the key to success, but with digital product passports, more than ever, your product labels become a communication tool that builds trust and reinforces accountability that define your brand and determine its success.

Strengthening Supply Chain Compliance

Compliance is one of the strongest drivers behind digital product passports.

With centralized lifecycle data, companies can more easily:

- Meet environmental and regulatory standards

- Verify supplier practices

- Track products across global markets

- Manage recalls efficiently

Improved traceability also reduces product counterfeiting risks. By linking each product to verified digital records, brands protect their reputation and ensure authenticity. For supply chain teams, digital product passports improve visibility and reduce operational blind spots. For consumers, they provide confidence in product claims.

Enabling End-to-End Product Traceability

Digital product passports support true end-to-end traceability, from source to shelf. By tracking materials, components, and finished goods in real time, companies gain deeper insight into product performance and environmental impact. This improves lifecycle management and supports responsible sourcing decisions.

Enhanced traceability also simplifies audits and regulatory reporting, helping organizations respond quickly to disruptions or compliance checks.

Implementation Considerations

Adopting digital product passports requires careful planning. Businesses must integrate data systems, align supply chain partners, and ensure secure data management across every stage of the product lifecycle.

Success depends on building scalable digital infrastructure, fostering collaboration across the supply chain, and maintaining strong data governance and cybersecurity standards. While implementation requires investment, early adoption positions companies for long-term regulatory readiness, greater operational efficiency, and stronger resilience in an increasingly transparent market.

Supporting Smart Packaging and the Circular Economy

Digital product passports are a foundation for smart packaging and circular economy strategies.

They provide the data needed to:

- Improve material tracking

- Encourage recycling and reuse

- Reduce environmental impact

- Deliver transparent sustainability reporting

As regulatory pressure increases and consumer expectations grow, digital product passports will become standard practice across industries.

Why Digital Product Passports Matter Now

Digital product passports are no longer a future concept, they're here and they're changing the game for better. By enhancing packaging transparency, improving traceability, and strengthening supply chain compliance, they help businesses meet regulatory demands while building consumer trust. Organizations that act now will be better positioned for a more transparent and sustainability-driven market. But digital product passports are only as effective as the systems supporting them.

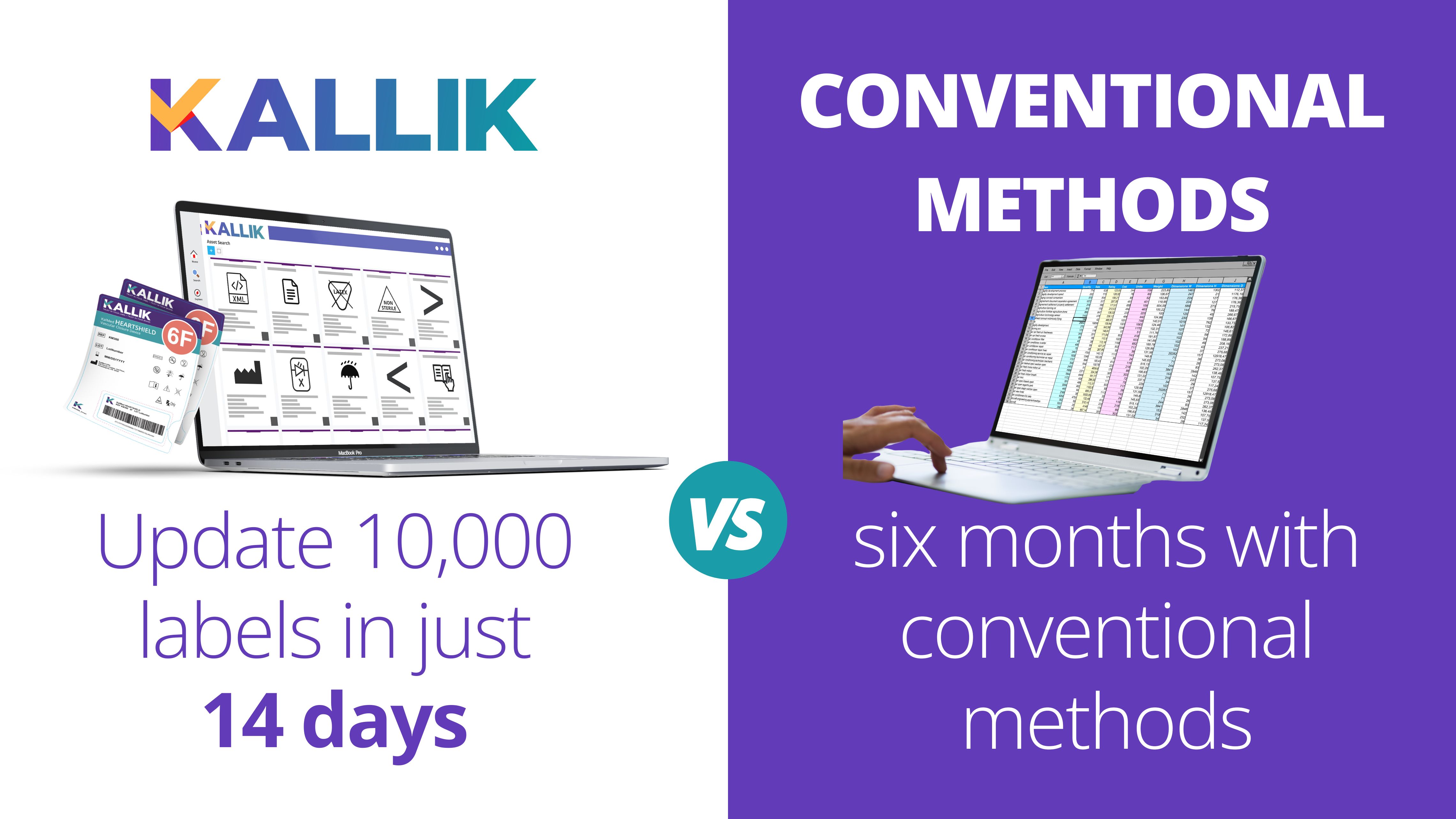

To meet evolving EU requirements and global compliance standards, businesses need accurate, connected product data that can be updated quickly and deployed at scale. If your current label and artwork management system cannot support rapid, controlled changes across markets and SKUs, it may be limiting your ability to respond to regulatory pressure.

Now is the time to strengthen your foundation

Solutions like Veraciti™ help organizations centralize product data, streamline artwork and labeling updates, and maintain compliance with confidence. By connecting product information with packaging execution, you can move faster, reduce risk, and deliver the transparency today’s market demands. Take a look at our partnership with Kenvue as an example of how we help businesses significantly increase speed-to-market without compromising on accuracy or quality.

Why not speak to one of our labeling and artwork experts to find out more? Fill in a form, email enquiries@kallik.com or check out our case studies to see real-world examples of how we’ve helped some of the biggest global manufacturers.

Frequently Asked Questions About Digital Product Passports

What is a digital product passport?

A digital product passport is a structured digital record that stores detailed information about a product’s lifecycle. This includes raw material sourcing, manufacturing processes, environmental impact, compliance documentation, and recycling instructions. It is typically accessed through QR codes, NFC tags, or other smart packaging technologies.

Why are digital product passports important for packaging transparency?

Digital product passports enhance packaging transparency by linking physical packaging to verified digital product data. Consumers, regulators, and supply chain partners can instantly access information about product origin, materials, sustainability metrics, and compliance status. This improves trust and accountability across the value chain.

Are digital product passports required in the EU?

The European Union is leading adoption of digital product passports as part of its sustainability and circular economy initiatives under the European Green Deal. EU digital product passport requirements are being introduced across specific product categories, with broader implementation expected over time. Companies operating in the EU market should prepare for evolving regulatory obligations.

How do digital product passports improve supply chain compliance?

Digital product passports centralize lifecycle data, making it easier for organizations to meet environmental regulations, verify supplier practices, manage audits, and respond to recalls. By improving traceability and documentation, they reduce compliance risks and support more efficient reporting processes.

How do digital product passports help prevent counterfeiting?

Each product can be linked to a unique digital record, allowing brands and consumers to verify authenticity. This reduces the risk of counterfeit goods entering the supply chain and helps protect brand integrity.

What technologies support digital product passports?

Digital product passports are typically enabled through:

- QR codes

- NFC chips

- RFID tags

- Cloud-based data platforms

- Product lifecycle management (PLM) systems

These technologies connect physical packaging to secure digital data systems.

How do digital product passports support the circular economy?

By providing detailed information about materials, carbon footprint, repair options, and recycling instructions, digital product passports support reuse, refurbishment, and responsible disposal. This aligns with circular economy principles and helps reduce environmental impact.

What industries will be most affected by digital product passport regulations?

Industries expected to see early or significant adoption include:

- Consumer goods

- Electronics

- Textiles and fashion

- Automotive

- Packaging and materials

- Food and beverage

However, digital product passport frameworks are expected to expand across many sectors as sustainability regulations increase.