Labeling errors can have serious consequences including regulatory fines, product recalls, and damage to your brand’s reputation. In industries like food and beverages, pharmaceuticals, and medical devices, small mistakes such as missing ingredients or outdated product information carry significant risks.

As labeling regulations continue to evolve, it’s more important than ever for businesses to adopt systems that prevent errors. Failing to do so can result in legal complications, safety issues, and lost consumer trust.

In this article, we’ll explore some of the most common labeling mistakes and provide practical tips to help you avoid them. By improving your labeling practices, you can ensure compliance, protect your brand, and keep your customers safe.

Inaccurate or missing product information

Inaccurate or missing product information can have serious consequences, with missing allergen details being one of the most common causes of food recalls. Research from The Institute of Global Food Security found that between 2016 and 2021, missing allergen information was responsible for more than half (57.6%) of all food recalls.

While minor incidents involving missing allergen information have occurred over the years (such as Tesco’s cheese and onion crisps mistakenly labelled as salt and vinegar, or Waitrose’s nut-free chocolate cupcakes that actually contained nuts) more serious mistakes have also come to light.

One of the most tragic cases involved 16-year-old Natasha Edan-Laperouse, who died after eating a pre-packaged baguette from Pret A Manger that contained allergens to which she was severely allergic. An investigation revealed that a food labelling ‘loophole’ had allowed the proper allergen information to be omitted.

In response, 'Natasha’s Law' was enacted in October 2021, requiring food retailers to include full ingredient and allergen information on every food item. Businesses that fail to comply with this law can face serious penalties, potentially including major fines or even imprisonment in severe cases.

While new laws are in place to prevent such catastrophic events, there is still room for improvement in ensuring complete accuracy. This is where automated labeling software could help to ensure that your products contain all the essential information, every time.

How to avoid inaccurate product information

When working in silos, information has to be pulled from multiple departments and sources; many of which might not contain the latest data; whether a new ingredients list or dosage recommendation.

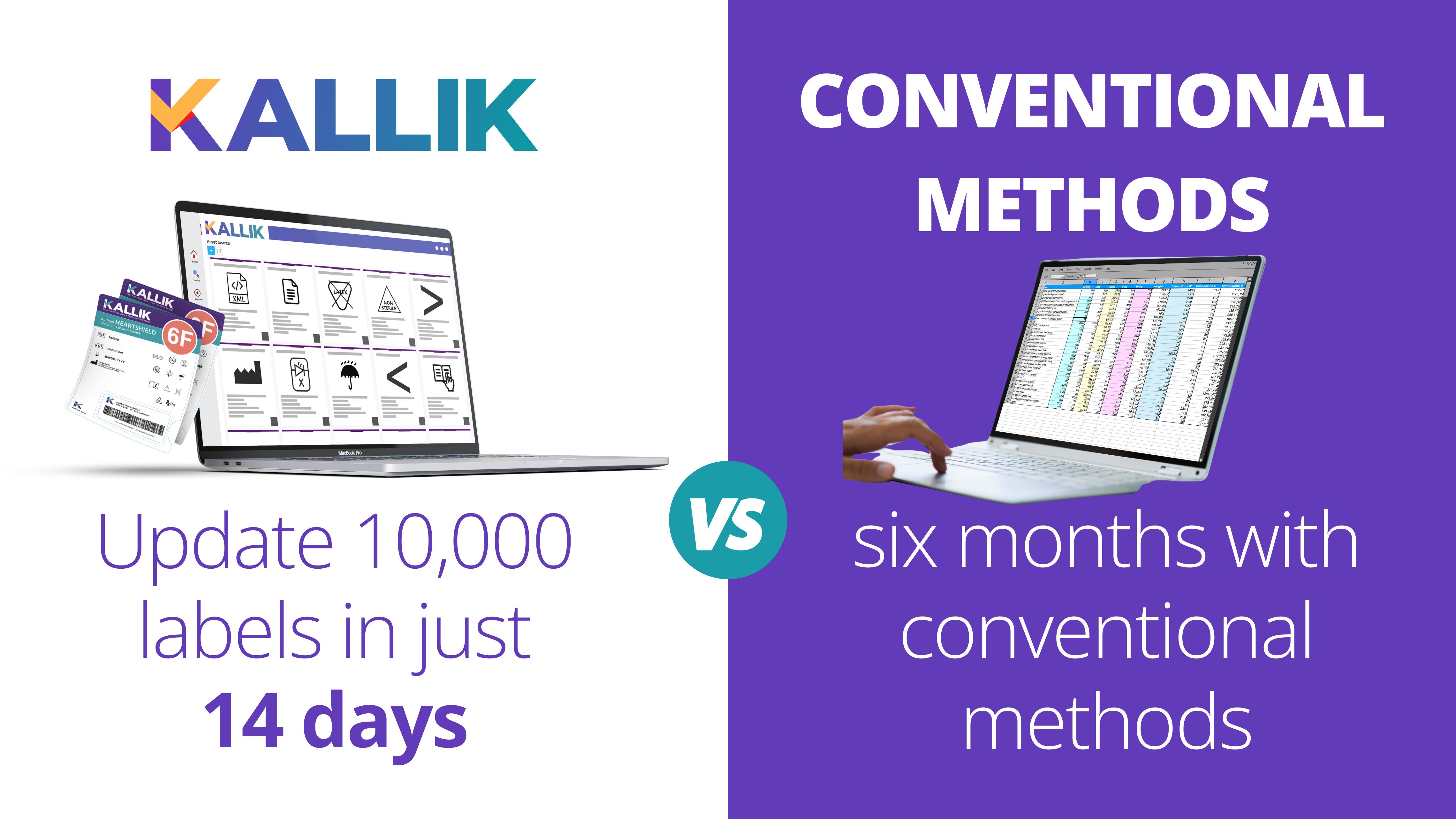

Kallik’s labeling and artwork management solution contains automated data management tools, enabling your teams to pull information from a central database to ensure 100% accuracy.

That single repository, alongside robust traceability features that help you track each cycle of a label’s life, and a breakdown of each data point, will ensure your business remains fully compliant and that it lands on shelves in good time, keeping consumers safe.

Non-compliance with regulatory requirements

Labeling regulations are mandatory for getting products, whether food, medical devices, or medicines, onto the shelves. Failure to comply with these regulations can have severe consequences.

In 2003, the world’s largest drug manufacturer, Pfizer, was in the spotlight for labeling errors on its hormone replacement therapy drug, Prempro. It was reported to have miscommunicated information about its dosage recommendations and instructions regarding its consumption – a legal requirement set out by the FDA.

Already in hot water for its confirmed links to breast cancer, and a subsequent fall in sales, Pfizer’s latest error resulted in 6,000 lawsuits and a payout of almost $1billion dollars to cases who believed they’d been put at risk of a breast cancer diagnosis.

These problems aren’t isolated to just the pharmaceuticals industry, either. In fact, according to a three year investigation into the chemical industry by EU authorities, as many as a third of chemicals reportedly break EU safety laws. One of the most common causes of regulation breakdown is in relation to REACH; Registration, Evaluation, Authorization and Restriction.

In one instance, in 2019, chemicals company, BASF, was found to have broken ‘important aspects’ of the EU’s REACH, by not carrying out crucial safety checks. Not declaring its effect on consumers meant that BASF landed hefty fines, totaling $173million dollars.

How to avoid regulations misery

With so many new regulations coming into force in 2025, including EU MDR, the Windsor Framework and 21 CFR Part 211, it can be hard to stay on top of each change if you’re relying on manual or siloed systems.

Instead, having access to an automated labeling and artwork solution that not only tracks regulatory updates, but also automates compliance checks across regions to ensure you’re meeting requirements for different sectors, is fundamental to navigating this complex series of changes.

Inconsistent branding and artwork

While regulations are a critical element of any label, so too is the branding. With counterfeiting on the rise across the chemicals and pharmaceutical industries, consistency in branding and the authenticity that brings has never been more important.

In the medical device and pharmaceutical industries, it isn’t uncommon for companies to make brand consistency errors, due to the number of mergers and acquisitions that take place on a frequent basis. Key to both of these markets though, is consumer trust, and when a company’s branding looks inconsistent across product lines, it can sour the value of the brand and the promises made to customers.

Some have made mistakes over the years, such as a major medical device company that, after launching a slew of new products, faced customer complaints about branding inconsistencies. These included mismatched product names and logos, prolonged editorial review processes, and deviations from the company's corporate content style.

While it’s not breaking any regulations, a lack of consistency in its consumer-facing products could have damaged its reputation.

How to avoid brand inconsistency

Maintaining consistency in branding and artwork across your product labels requires robust systems and processes. This is where artwork management software can make a significant difference.

By centralising your artwork files and enforcing version control, Kallik’s artwork management software ensures that all teams—whether they’re in marketing, regulatory affairs, or production—are working from the same approved assets. This eliminates the risk of outdated logos, mismatched fonts, or inconsistent product names creeping into your labels.

By implementing a solution like this, businesses in highly regulated industries can not only protect their brand reputation but also build consumer trust through cohesive, professional, and consistent labelling across all products.

Lack of version control

Manual or siloed systems can often mean that old branding, regulations or obsolete files are pulled from folders and used on new product labels. In error, these labels can be approved and distributed, making their way to shelves and potentially putting customers at risk. This can be particularly detrimental in the pharmaceutical industry, where policies and regulations, ingredients and dosage recommendations, change frequently.

Keeping up with the changes, while relying on manual systems to ensure you remain compliant, is likely to be an impossible task. One that could both lead to you breaking all-important FDA guidelines, resulting in legal action and hefty fines, and significant delays to supply chains, meaning your products are off the shelves for longer.

How to avoid using outdated labels

Adopting labeling software that contains version control will provide you with complete traceability over your product’s life cycle, to ensure consistency and accuracy across each product, thanks to pre-approved templates.

With version control, you can rest knowing that only the latest, approved files will be printed.

Errors in multi-lingual labeling for global distribution

Another common labeling error for multinational companies is incorrect translations.

Take a food and drink company, for example. They’ll likely have products that have multiple SKUs, each distributed to hundreds of countries. Each of those SKUs will require its own multi-lingual labeling, helping to account for cultural differences and regulations regarding ingredients, so that consumers around the world will understand how to eat or drink, and store the product.

This problem, of course, isn’t limited to food and beverage manufacturers. In the medical device industry – according to the FDA – “any information associated with a device targeted to the patient or lay caregiver” must feature multi-lingual labeling. This could mean:

- Marketing materials.

- Product packaging.

- Product descriptions.

- User manuals (IFUs).

- Safety instructions.

- Accompany software.

- Any document that explains how the device should work.

During that process, you might even need to translate patient applications, applications for regulatory approval, patient information sheets and clinical trial forms into the language of the Member State (according to EU MDR regulations). Failure to do so could result in significant fines.

How to avoid multi-lingual labeling errors

Managing multi-lingual labeling for global markets requires robust processes and the right tools. Labelling and artwork management software centralises all assets and translations, ensuring approved versions are used consistently across SKUs. These platforms also automate quality checks, flagging issues like missing translations or formatting errors before labels are finalised.

In addition to using software, partnering with certified translation providers ensures accuracy and cultural adaptation. Maintaining a centralised translation memory—a shared database of approved translations—further enhances consistency across labels, packaging, and user manuals.

Case study

We recently worked with a leading Danish company, Ambu, who specialize in single-use endoscopy solutions and diagnostic and life-supporting equipment. Following a major expansion of their product line, their team quickly realized that their existing labeling, and outdated labeling management system, was inadequate for their growing needs.

They found that “the absence of an efficient, all-encompassing system hindered compliance maintenance and label management across their extensive product portfolio” – a problem which our end-to-end cloud-based software, Veraciti, soon solved.

With access to a single version of truth, to manage and version all phrases, imagery and translations, Veraciti enabled them to control the labeling of tens of thousands of their products, the artwork and multiple-language information for each, all without risking non-compliance.

Poor proofing and approval processes

We’ve seen countless businesses fall foul to rushed proofing, including beverage giant, Coca-Cola. Earlier this year, it recalled over 13,000 cases of its Minute Made Zero Sugar Lemonade because they actually contained the regular, full sugar, lemonade. For consumers who consciously avoid sugar intake, because of diseases like diabetes, this could spell disaster, as the FDA confirmed.

This case demonstrated that no company was immune to labeling challenges. In fact, we’ve found even some of the world’s biggest companies lack robust and reliable labeling management systems, leading to proofing and approvals black holes, the breaking of critical regulations and shipment delays.

How to avoid proofing and approval pitfalls

A manual labeling and artwork management process can sometimes involve over a dozen people – from your own internal production and labeling management team, to the legal department and your design agencies. With so many people involved, spread across a range of offices and solutions, it’s hardly a surprise that human errors are regarded as one of the most common reasons for labeling errors.

With automated workflows, approvals and version control at your fingertips though, software can be your greatest ally. Not only will it help you maintain traceability of each stage of a label’s lifecycle, preventing error and improving safety, thanks to a full audit log and approval flow, it also holds a secure, up-to-date and approved set of digital assets, that are pre-approved – so that no unapproved assets are ever used.

Manual data entry and lack of automation

Paper-based processes are slow and cumbersome. Even worse, manual, or siloed processes put important tasks like data input at risk. Errors or oversights could include incorrect hazard statements on chemicals or inaccurate ingredients on pharmaceutical product packaging. These scenarios not only put customers in harm’s way, but also break a number of regulations like the OSHA Hazard Communication Standard (OSHA HSC); designed to ensure chemical safety in the workplace.

These methods also slow down the manufacturing process, making problems harder to identify and recover from.

Our labeling and artwork management expert, Liam Conlin emphasizes the importance of investing in the right software to ensure compliance: “Investing in a solution like Veraciti, that was built and designed with compliance in mind, isn’t just about meeting today’s compliance requirements—it’s about safeguarding the future. Over time, it can save businesses hundreds of thousands, if not millions, in potential fines and recalls. More importantly, it helps prevent mistakes that could have life-threatening consequences for patients or consumers.”

How to avoid data entry errors

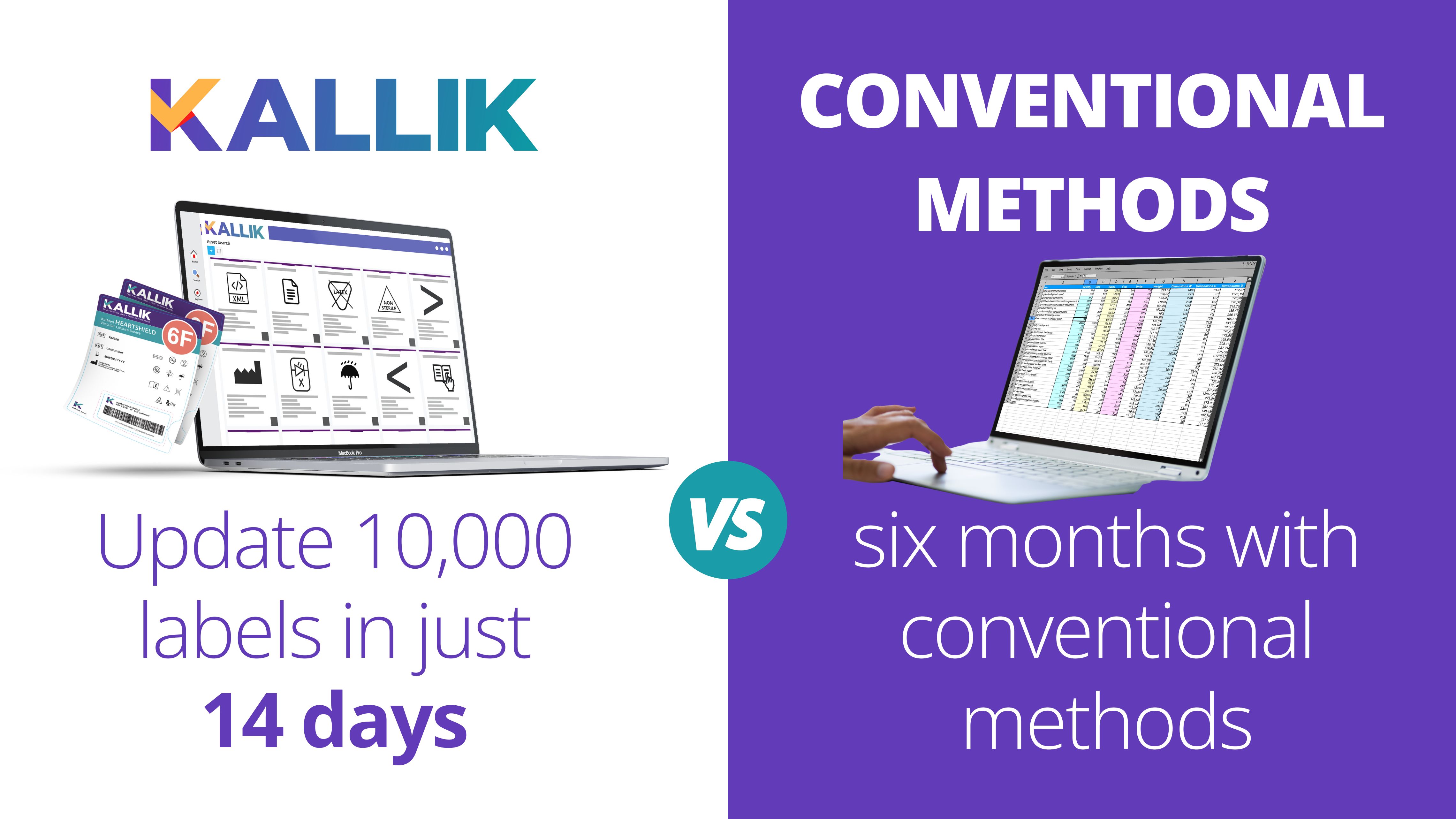

At its very heart, automation is about the process of using technology to perform tasks with minimal human intervention. It not only reduces labor-intensive tasks, boosting productivity and ensuring consistency, but also significantly minimizes human error, shortens cycle times by up to 70%, and eliminates mistakes entirely—enabling products to reach shelves faster.

Integrating your ERP (enterprise resource planning) databases, with a labeling system will help to ensure that any data from across the business is securely saved in one platform, allowing your teams to manage and extract data instantly. ERP systems in the pharmaceutical industry, for example, are invaluable, serving as centralized hubs for storing and managing critical information like ingredients, dosages and warnings.

Interoperability between an automated solution like Kallik’s Veraciti, and your ERP, is integral to ensuring the correct information is used at all times, keeping consumers safe, shoring up your supply chain and procurement process, as well as ensuring complete accuracy and consistency.

Summary

In fast-paced, costly and highly-regulated industries, there can be a temptation to wait to invest in an automated labeling management system when it’s really needed, with thoughts of an arduous onboarding and migration process deterring you from making the investment.

You might even feel you have a qualified and well-equipped team, and design agency, to support your operations right now, and the technology you need to meet those requirements.

Consider though, how your business may look in five years’ time. It’s inevitable that businesses evolve; they grow, innovate and develop new products, reach new markets and wider audiences. In the same vein, businesses can also lose employees, and strategies to grow can be stifled by less experienced teams, the cost of onboarding new members, and outdated technology.

Any highly-regulated business should recognize the importance of being agile and proactive, in an effort to mitigate disaster, risk or ill health – in favor of maintaining trust and reputation.

With an automated labeling and artwork management solution, non-compliance could be a thing of the past; helping to reduce risk, inaccuracy and inconsistencies, improve productivity and efficiency.

If your business is on the cusp of its next period of growth, or you’re considering taking the plunge to guarantee compliance in your industry, visit the website for a demo on its range of features, including our Assisted Technology of Migration tool (AToM), or contact our team for a consultation.

Button ExampleView our brochure