Mary Kay Simplifies Global Labeling, Ensures Compliance, and Boosts Efficiency

For more than half a century, Mary Kay Inc. has empowered women while revolutionizing the world of business. Today, the Texas-headquartered multinational is a multi-billion-dollar organization with millions of independent sales consultants in nearly 40 countries. With such a vast global footprint, Mary Kay relies on robust, scalable, and compliant packaging and labeling processes to serve diverse markets effectively.

Kallik’s Veraciti solution has enabled Mary Kay to move from legacy, document-driven processes to a content-centric approach, unlocking automation, improving compliance, and delivering efficiencies across global markets.

Challenges

Mary Kay’s growth into nearly 40 global markets exposed limitations in legacy labeling and artwork processes:

- A document-driven approach concentrated content entry in one place, causing duplication, lack of ownership, and slower responses to regulatory-driven changes.

- Multilingual requirements created very high complexity: insert content in many languages with many fields and strict ordering.

- Translation inefficiencies caused repeated requests and inconsistent phrasing across pack types.

- Finding and updating all artworks affected by a change (for example address changes) was time-consuming.

From the Mary Kay case materials, the business made the need clear: they needed a global system that enabled ownership of content while tracking and tracing changes centrally.

The Kallik Solution

Mary Kay selected Kallik’s Veraciti because it offered a full-circle, content-centric platform that automated artwork generation, centralized content and translations, and provided robust “where used” search and reporting. Key capabilities include:

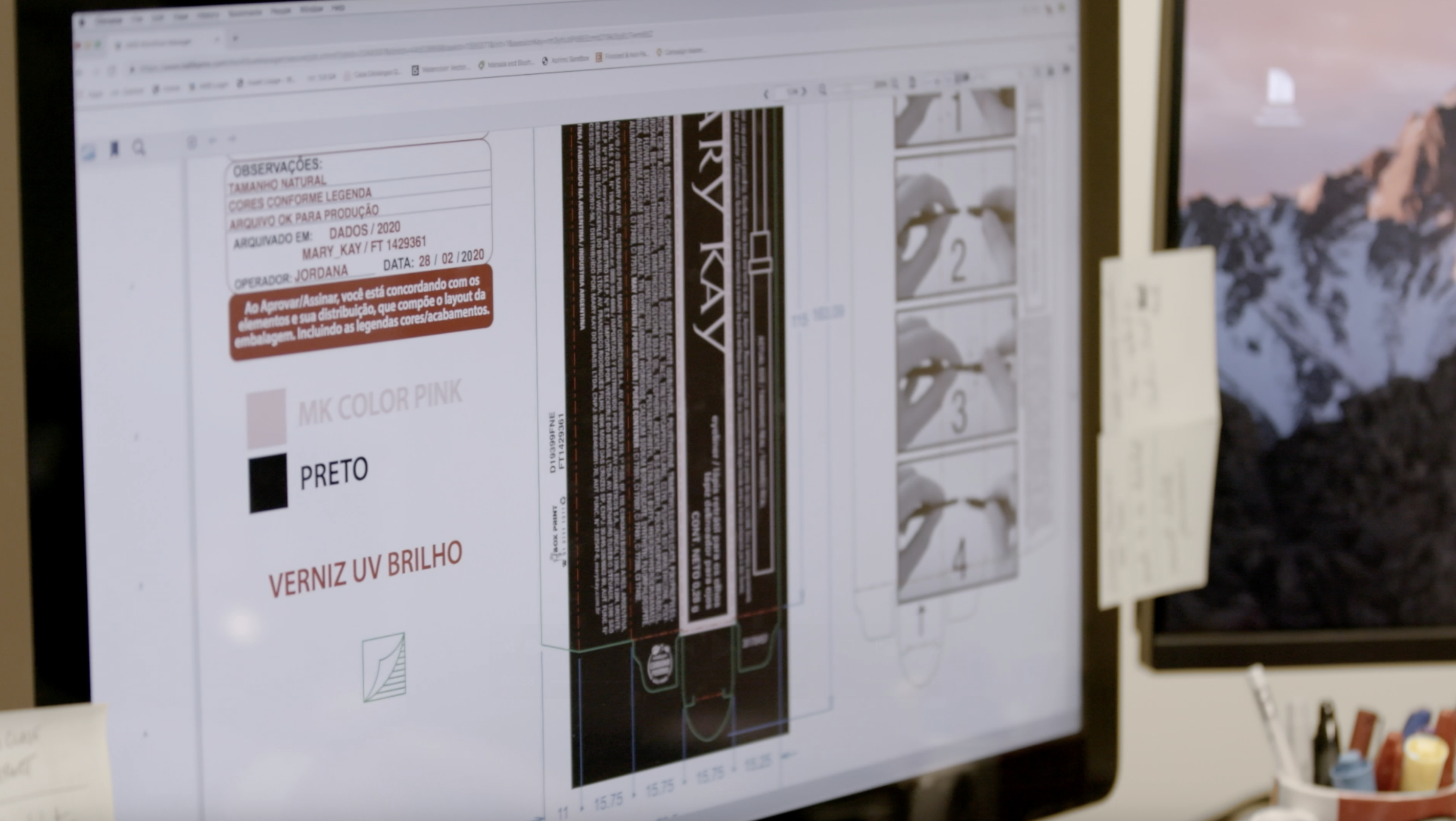

- Semi-automated artwork (Cascade plugin) to populate templates and generate multilingual inserts automatically.

- Phrase Manager to centralize and re-use approved copy and translations.

- Where Used functionality to locate and update every artwork impacted by a change.

- Cloud collaboration to enable global teams and external partners to work from a single source of truth.

Key features delivering value to Mary Kay include:

Semi-Automated Artwork Creation: The Cascade plugin allowed production artists to automatically generate packaging artwork templates in multiple languages, drastically reducing manual effort and risk of error.

Phrase Manager for Consistency: Veraciti’s Phrase Manager centralized translations, eliminating duplication, ensuring consistency across products, and cutting translation costs for subsidiaries.

Where Used Functionality: Enabled rapid identification and updates of all artworks impacted by regulatory or business changes — for example, when Mary Kay updated facility addresses globally.

Cloud-Based Collaboration: Provided a single, centralized platform accessible to global teams and external partners, increasing transparency and accountability.

“Kallik’s unique selling point was the ability to automate artwork. It was the only company that could deliver this functionality.” Emma Polman, Manager, Creative Business Packaging, Mary Kay Inc.

The Results

With Kallik’s Veraciti in place, Mary Kay has transformed its packaging and labeling operations:

Faster Artwork Creation: Significant reduction in time to create and edit artworks, freeing resources to focus on additional marketing projects.

Streamlined Translations: Efficient management of translations across 17+ languages, ensuring accuracy and eliminating repeated requests.

Regulatory Agility: Quick and accurate updates across global packaging whenever regulations or business data changed.

Improved Data Flow: Automatic data transfer between systems (e.g. Agile and PIM), ensuring a single source of truth and reducing errors.

Scalable for Growth: Simplified entry into new markets, including South America, with the ability to easily incorporate country-specific labeling requirements.

“Veraciti has vastly simplified our entry into new markets such as South America, as in countries such as Columbia we needed to have country specific data on labeling and packaging." Colleen Maxwell, Digital Media & IT Professional, Mary Kay Inc.

Business Benefits at a Glance

- Optimization of global labeling and artwork processes

- Reduced time and resources needed for translations

- Faster regulatory response times, lowering compliance risk

- Automated artwork generation, improving efficiency and accuracy

- Extended best practices into promotional materials and beyond

A Trusted Partnership

Mary Kay also values Kallik’s collaborative, forward-thinking approach: “The Kallik staff have been great partners on this journey. They listen, they evolve the system, and we’re excited about where this partnership will take us next.” With Veraciti, Mary Kay has not only modernized its global labeling processes but also future-proofed its operations to support growth, compliance, and consistency across every market.

Want to know more?

You can watch the full case study video here to find out more about how we helped Mary Kay. Why not see what Kallik can do for your business with a future-proof, end-to-end, fully digital labeling process? Speak to one of our experts today by calling +44 (0) 1827 318100 or emailing enquiries@kallik.com.